Established in 1994, GMT Global Inc started business in precision mold components manufacturing and selling in the early days to fix painful points for customers based on initial believe persistently. Prior to a decade further, the managing director, Mr.Tony Chen, realized needs of mold market got weak while massive mold builders moved out of Taiwan, the timing to make change. Thus, the company began to develop automation use components, as well as supplied good profit OEM parts for semi-conductor facilities.

However, in consideration for company’s growth in the future, Tony decided to create the brand GMT, to sell own designed and produced products, urged the company move on a completely new road,in 2006, when GMT brand name was born. From then on, GMT dedicated itself to develop innovated products, optimize manufacture procedure and improve machining technologies; those were implemented to management of offering technical profession to serve customers.

Capabilities of development and innovation accumulated in decades, the company engaged to high precision application of automatic inspection in smart phone industry in 2015. The case example after the company’s change performed itself in automation industries with the preparation of technical abilities and capability for Industrial 4.0. First consolidating capacity for parts and components, then, upgrading to modularization and systematic integration, thereby maintaining its place as the most competitive firm on the market.

Recent virus impacts on management of enterprises. GMT stay tune of the company goal, and take place of trainings to employees for knowledge improvement, and development constantly by implement of Lean Manufacturing, SPC (Statistic Process Control), OKR (Object Key Result) those management tools for stepping forward to future.

In an interview with SmartStateInda, Mr. Tony Chen, GM. GMT elaborates about companies vision to build intelligent automation territory for industries.

Company Emphasis

GMT is aimed to provide “Total solution” for customers to solve their problems. Therefore, GMT emphasizes on vertical integration including automation key components, industrial modules, industrial automation sub-system, and then gradually to industrial automation ICT and control.

How GMTGlobal solution changing the face of industrial ecosystem

GMT insists on the vision which is to “build intelligent automation territory, and accomplish the convenient dream for industries”. Our best fit solutions focus on convenience and easy-to-use automation products to speed up the process of automation. GMT believe that automation is no longer a dream and GMT will help to accomplish your automation achievement!

Elaborate about your Electric Cylinder Series.

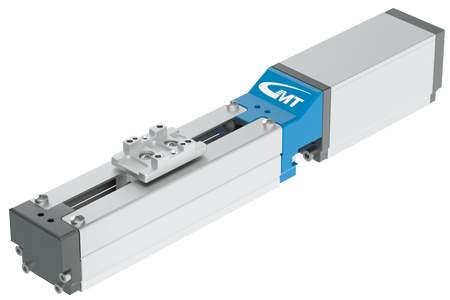

GMT’s electric cylinder series include follows,

1) short-stroke slider cylinder : GECA/GECB/GECC

2) long-stroke slider cylinder : GECF/GIRC/GIRO/GERC/GESC.

3) rode type series : GECD/GECE/GECX.

In addition to the various options of mechanical types, GMT could also help customers to select the compatible motor, driver, encoder and controller according to customers’ different requirements.

Tell us about GMTGlobal’s Precision solutions

GMT have 95% self-production rate, we could not only possess the core technology, but also introduce automation products with stable manufacturing ability and good quality. Furthermore, in order to satisfy customers’ requirements, GMT is capable in product integration by providing one-stop service and evaluating of customized projects.

Why India is a key market for GMTGlobal?

There are many great potential industries of India market including smartphone, electronics, biomedicine, green energy, photonics as so on. Those industries are also requiring delicate automation application to improve production efficiency and quality. GMT is specialized in automation products over a decade and has been helping many customers from different countries in accomplishing many outstanding projects. GMT have confidence to facilitate customers from Indian market in broaden further horizon.

22 comments

atorvastatin 40mg us atorvastatin online order atorvastatin 20mg oral

ciprofloxacin 500mg price – buy cheap generic ciprofloxacin oral erythromycin

ivermectin 12mg tablets for humans – buy sumycin no prescription sumycin 500mg cheap

ivermectin 6mg without prescription – order ciprofloxacin pill tetracycline price

purchase furosemide – buy cheap generic warfarin capoten 120mg sale

metformin for sale – order bactrim generic where to buy lincocin without a prescription

retrovir price – lamivudine 100mg oral zyloprim ca

quetiapine 100mg ca – eskalith brand buy eskalith online

hydroxyzine 10mg cheap – order escitalopram without prescription buy endep for sale

cleocin 300mg ca – buy cefixime online buy chloramphenicol pills for sale

ivermectin order online – purchase cefaclor online cheap buy cefaclor sale

buy ventolin inhaler – fluticasone us theophylline online

can i buy medrol online – loratadine brand buy astelin 10ml

order metformin pill – precose price acarbose 50mg brand

buy micronase 2.5mg generic – actos 30mg for sale brand dapagliflozin 10mg

buy repaglinide 1mg generic – order jardiance 10mg online purchase empagliflozin

order generic semaglutide 14 mg – order glucovance pills desmopressin over the counter

buy famciclovir 250mg online cheap – where can i buy famciclovir buy valcivir 500mg pills

nizoral 200mg us – nizoral cost itraconazole 100mg price

purchase lanoxin without prescription – lanoxin 250 mg brand buy furosemide medication

purchase metoprolol online – nifedipine pill cheap adalat 30mg

microzide buy online – buy norvasc generic bisoprolol 10mg us